Analysis of Key Performance Indicators of Pressure Transmitters - Starting Drift

Cause analysis

Temperature factors: The sensitive components and circuits inside the pressure transmitter are extremely sensitive to temperature changes. At the moment of startup, there is a difference between the internal temperature of the device and the ambient temperature, which will cause the physical properties of the sensitive components to change. Taking the diffused silicon pressure sensor as an example, the change in temperature will affect its resistance value, thereby changing the output of the measuring bridge and causing starting drift.

Characteristics of electronic components: At the moment of power-on, the electronic components inside the pressure transmitter, such as capacitors and inductors, will undergo a charging and discharging process, which will cause voltage and current fluctuations in the circuit. These fluctuations may interfere with the normal output of the transmitter and cause start-up drift. In addition, the aging of electronic components will make this phenomenon more obvious. As the use time increases, the performance of the components gradually becomes unstable, and drift is more likely to occur at startup.

Mechanical stress effects: Mechanical stress generated during installation may affect the measurement of the pressure transmitter when the device is started. For example, vibration of the pipeline, improper tightening during installation, etc. may bring additional stress to the transmitter, causing slight changes in the internal structure of the sensor, thus causing start-up drift.

Test method

Test conditions:

1. Ambient temperature 20℃±2℃

2. Relative humidity ≤80%

3. Atmospheric pressure 86kPa~106kPa

4. Magnetic field: No external magnetic field that affects the output of the pressure transmitter

5. Vibration: No vibration source that affects the output of the pressure transmitter

6. Power supply: Should comply with the power supply performance index marked on the test sample

Test procedure:

1. Before the test, the pressure transmitter should be placed under reference working conditions for 12 hours, but without power supply.

2. Turn on the power supply, apply a 10% input signal to the pressure transmitter, and record the output value after 5 minutes, 1 hour and 4 hours.

3. Disconnect the power supply of the pressure transmitter and place it under atmospheric conditions for at least 12 hours.

4. Repeat test 2 with 90% output signal and record the measurement results.

Judgment conditions:

At 10% and 90% of the measurement range, the output value change should not exceed the absolute value of the indication error".

Microcyber's single crystal silicon pressure transmitter uses a single crystal silicon piezoresistive pressure sensor, built-in high-resolution ADC, high-performance measurement and amplification chips, with stable output, and its starting drift is less than 0.075% URL.

Monocrystalline silicon pressure transmitter

Microcyber's monocrystalline silicon pressure transmitter uses a monocrystalline silicon piezoresistive pressure sensor with a built-in high-resolution ADC, which can provide a step effect of up to 250ms (different ranges will have certain differences), meeting the more stringent working conditions on site.

Some performance indicators of the monocrystalline silicon pressure transmitter are as follows:

· Support the latest versions of HART, FF H1, PROFIBUS PA, and PROFIBUS DP protocols,

· Pass the HART, FF, PA, and DP interoperability certification tests.

· Pressure types include: gauge pressure, absolute pressure, and differential pressure.

· Highest accuracy: ±0.075% full scale (20℃℃, range ratio 10:1 range)

· Long-term stability: ±0.2% range upper limit/5 years.

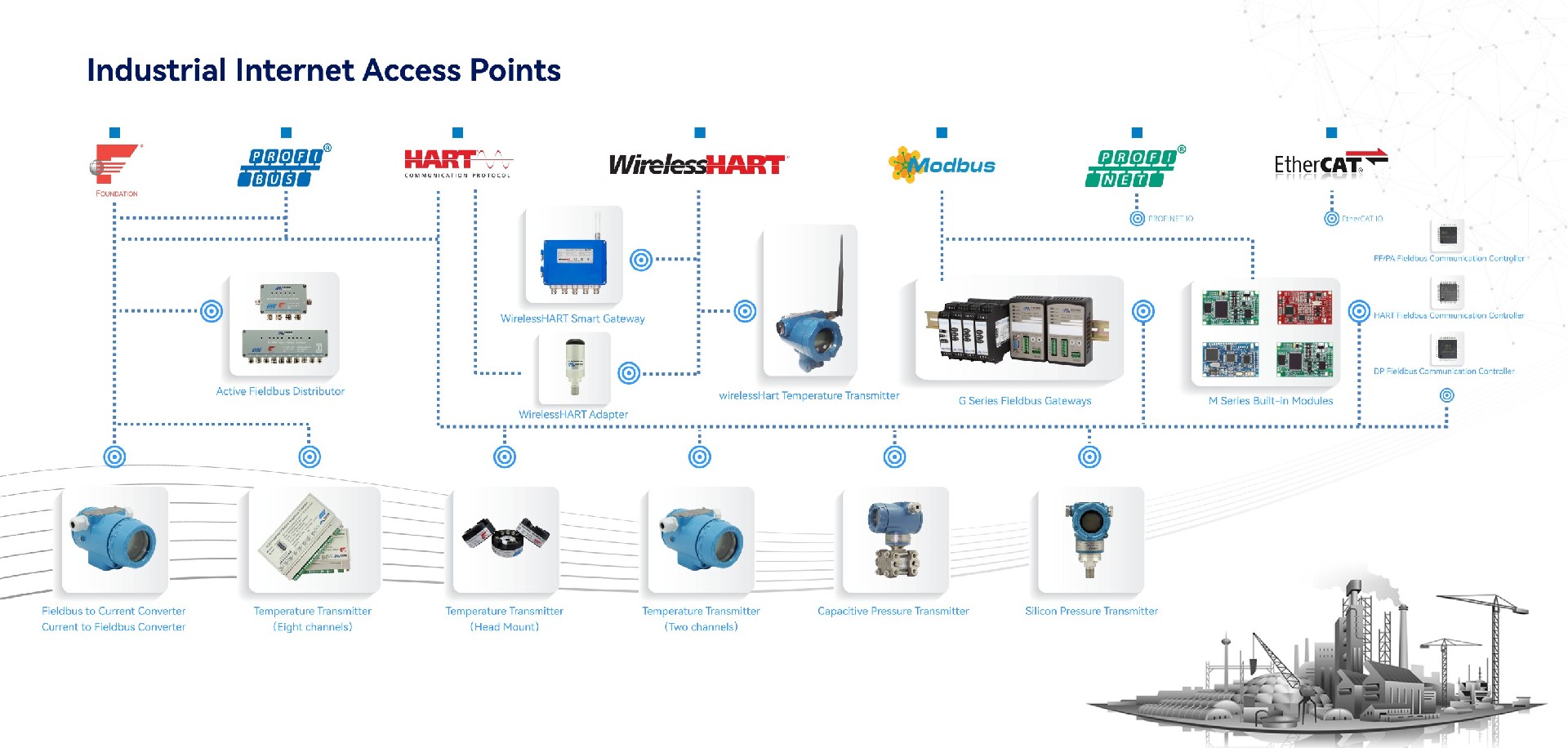

Industrial Internet Access Point

Microcyber is committed to the research and development, production, sales and integrated application of industrial IoT products.

Microcyber is the first fieldbus protocol stack in China and the third in the world to pass international certification, the first fieldbus instrument in China to pass international certification, the first demonstration application of networked control system in China, and the first function in China to pass international certification, the first wireless HART product in China to pass international certification, etc.

Microcyber is one of the main undertaking units of important national science and technology projects in the fields of industrial Internet of Things and industrial automation. Over the years, we had undertaken a number of major national science and technology projects, the National High Technology Research and Development Plan (863 Plan), and the development of intelligent manufacturing equipment. Special projects and other national science and technology plans.

Microcyber has accumulated rich experience in technical capabilities, technical achievements and technical reserves, and has a strong R&D team to protect the sustainable development of the company's products.