Microcyber NCS-TT108 Multi-Point Temperature Measurement Solution(8-Channel Temperature Transmitter)

Industry Pain Points and Limitations of Traditional Solutions

For scenarios in process industries such as petroleum and chemical, metallurgy, and power generation, where temperature measurement points are highly concentrated on equipment like reactors, towers, and critical units, traditional single-channel temperature transmitter solutions present numerous unavoidable problems. These issues severely impact project construction efficiency and long-term operational benefits:

Numerous temperature points result in high cable volume and complex installation;

Large quantities of safety barriers and distributor boxes lead to high system investment costs;

Dispersed equipment increases maintenance and management costs;

Hinders the implementation of fieldbus and digital systems.

The NCS-TT08 series intelligent multi-input temperature transmitter, centered on the concept of "centralized acquisition and field transmission," provides a full-process, multi-point temperature measurement solution covering measurement, transmission, and integration. It is suitable for industrial sites with continuous process operation and high reliability requirements, helping clients reduce system investment and operational costs, and accelerating the construction of fieldbus and digital systems.

Core Architecture and Advantages of the Solution

Core Architecture

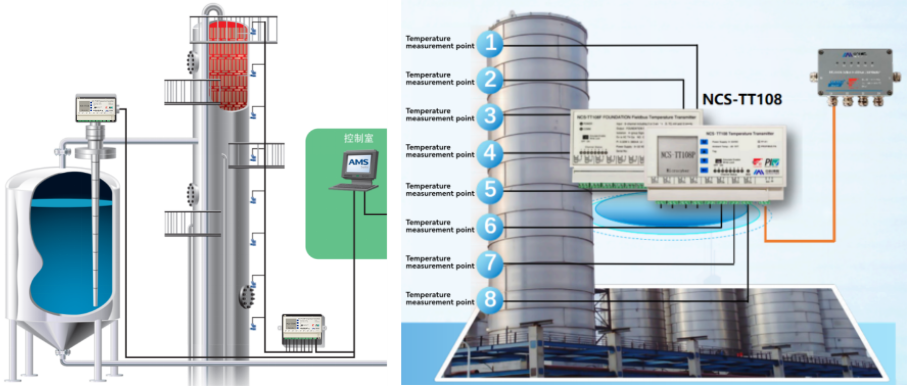

The NCS-TT08 series temperature transmitter adopts an extremely simplified "centralized acquisition + unified transmission" architecture. A single device integrates data from 8 temperature measurement points, then transmits it directly to the control system via one fieldbus or communication link, completely simplifying the traditional complex architecture involving multiple devices and links:

8 Temperature Points → 1 NCS-TT08 Transmitter → 1 Bus → Control System (DCS/PLC)

Core Advantages of the Solution

1.Cost Optimization: Integrated Design Reduces Lifecycle Costs

Equipment Simplification:One device replaces 8 traditional single-channel transmitters, reducing the procurement of auxiliary equipment like safety barriers and distributors;

Wiring Simplification:8 temperature signals are transmitted via one bus, significantly reducing cable and cable tray usage, lowering installation costs by over 30%;

Efficient Maintenance:Centralized device deployment facilitates easier inspection, calibration, and troubleshooting, reducing long-term operational costs by 40%.

2.Flexible Compatibility:Multi-Protocol Support for Various Control Systems

Multi-Protocol Support:Covers mainstream communication protocols in the industrial field, easily connecting to leading domestic and international DCS (e.g., Siemens, Yokogawa, Honeywell) and PLC systems without additional protocol converters;

Standardized Integration:Provides complete device description files, meeting standardized requirements for system configuration and data exchange, reducing integration time by 50%;

3.Accurate Measurement: High Stability Ensures Process Reliability

High Precision:Measurement accuracy better than Class 0.1, with low-temperature drift design (±50ppm/°C), ensuring long-term data accuracy;

Compensation Technology:Built-in high-accuracy thermocouple cold junction compensation module with compensation accuracy up to ±1.0°C, suitable for complex temperature environments;

Flexible Wiring:Supports RTD 2-wire and 3-wire connections, adapting to different field sensor installation requirements.

4.Safe and Reliable: Industrial-Grade Protection for Harsh Environments

Explosion-Proof Certification:Intrinsic safety explosion-proof certified. FF and PA protocols are certified by international organizations, enabling safe use in hazardous areas like petrochemical and chemical plants;

Environmental Adaptability:Customizable flameproof enclosures available to meet different field requirements;

Quality Assurance:Core components undergo strict screening. Products are proven in long-term industrial applications, with a Mean Time Between Failures (MTBF) exceeding 100,000 hours.

Typical Application Scenarios

Scenario 1: Multi-Zone Temperature Measurement for Reactors/Distillation Columns

In equipment like reactors and distillation columns, multiple temperature points are densely distributed across different zones. Adopting the Microcyber NCS-TT08 multi-channel temperature measurement solution enables localized centralized measurement and unified bus transmission, effectively reducing wiring and equipment investment, lowering the difficulty of opening holes on the tower and construction, and ensuring process stability through real-time data upload.

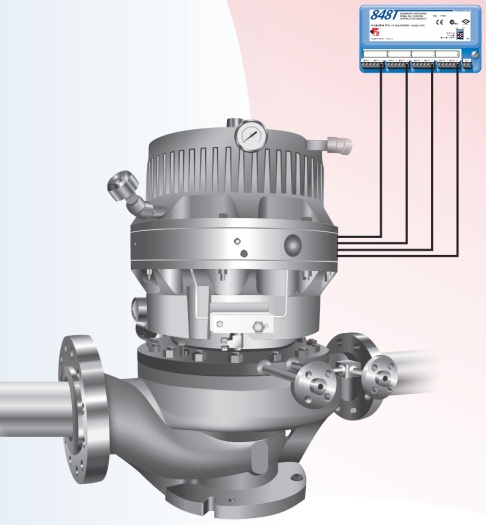

Scenario 2: Temperature Monitoring for Motors and Critical Equipment

For multi-point temperature monitoring of motors, pump sets, and critical equipment, the Microcyber NCS-TT08 multi-channel solution can simultaneously collect temperature from multiple parts such as the stator, rotor, and bearings. It provides real-time feedback on equipment operating status, offering data support for predictive maintenance and avoiding unplanned downtime.

Scenario 3: Metallurgy and Non-ferrous Metal Hydrometallurgy

In high-temperature, corrosive environments like zinc hydrometallurgy and copper smelting, the Microcyber NCS-TT08 multi-channel intelligent temperature transmitter has demonstrated long-term stable operation, reducing equipment failure rates and maintenance frequency, helping enterprises control production costs.

Partial Application Achievements

Industry | Cooperative Client / Project Name | Protocol | Application Status |

Metallurgy | Gansu Baiyin Northwest Lead-Zinc Smelter Zinc Hydrometallurgy Line | PA / FF | Long-term stable operation, recognized by the customer |

Chemical Industry | Hunan Hongrun Chemical Benzoic Acid Production Line | FF | Accurate data, significant reduction in maintenance costs |

Non-ferrous Metals | Jiangtong Yantai Guoxing Cathode Copper Energy Saving Project | FF | Adapted to smelting conditions, fault-free operation for over 3 years |

Cement Industry | Multiple cement production lines in Guangxi, Hebei, Anhui, Jiangsu | PA | Batch application, convenient system integration |

Microcyber NCS-TT08 multi-channel intelligent temperature transmitter Solution Value Summary

1. Architectural Innovation:Reconstructs the multi-point temperature measurement architecture with "1 device = 8 measurement points," eliminating the complex wiring and device redundancy of traditional solutions;

2. Controllable Costs:Reduces investment throughout the entire process from equipment procurement and construction to long-term operation, helping clients achieve cost reduction and efficiency improvement;

3. Stable and Reliable:Industrial-grade quality and precise measurement technology ensure continuous process operation and reduce the risk of unplanned downtime;

4. Digital Compatibility:Bus-based design and multi-protocol support perfectly align with the digitalization and intelligent upgrade needs of modern factories.

Microcyber NCS-TT08 multi-channel intelligent temperature transmitter Applicable Industries

1. Petroleum & Chemical, Fine Chemical;

2. Metallurgy, Non-ferrous Metals (Hydrometallurgy, Anode Refining, etc.);

3. Power & Energy (Auxiliary equipment in thermal power, nuclear power, etc.);

4. Cement, Building Materials;

5. Research Institutes, Laboratories (Multi-channel precision temperature measurement scenarios).