Factors Affecting Hysteresis Characteristics of Diffuse Silicon Pressure Sensors

Microcyber's NCS-PT105ⅡS series of intelligent pressure transmitter adopts advanced, mature and reliable piezoresistive silicon pressure sensor, combined with advanced microprocessor technology and digital capacitance measurement technology to make it carefully designed. The powerful function and high-speed operation capability of the internal microprocessor make the transmitter have excellent qualities such as intelligence, high precision, high reliability and stable zero point; the LCD module can display various physical quantities such as pressure, temperature and current; the key operation can realize various functions such as zero migration and range setting, which is easy for on-site debugging.

NCS-PT105ⅡS series intelligent pressure transmitter supports HART, FF, PA protocols, and can measure pressure, differential pressure, liquid level, flow and other industrial parameters, which can be widely used in petroleum, chemical, electric power, metallurgy and other industries.

With the development of semiconductor technology, the technical indexes of diffusion silicon pressure sensors are constantly improving, but the hysteresis nonlinear characteristic of diffusion silicon pressure sensors, which is inherent in unconventional and multi-value counterparts, limits their measurement accuracy. At present, domestic and foreign research on the hysteresis characteristics of the sensor is relatively small, the literature has proved that it can not be directly modeled using neural networks, most of the scholars work is the hysteresis nonlinear as a general nonlinear processing, the results can not meet the requirements of the compensation accuracy.

The working principle of diffusion silicon pressure sensor is: the use of semiconductor plane manufacturing process in the corresponding surface of the silicon cup made of resistance value of the same four diffusion resistors and through the appropriate connection of the diffusion resistors to form a Whiston bridge, when the diaphragm deformed by the action of the pressure, the resistance of the bridge changes accordingly, so that the bridge loses equilibrium, and then get the electrical signal corresponding to the pressure change to achieve the measurement of the purpose of pressure. Pressure measurement. The resistivity of the semiconductor material changes with the force, which is the piezoresistive effect.

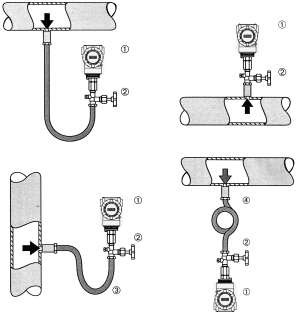

Pressure transmitter mounting method

1. Raw material

Any kind of semiconductor material, because of its internal organization and structure of the complexity of the relationship between the pressure by the external force in the tiny grains between the micro-strain will be generated, when in the disappearance of the external force, the micro-strain disappeared, but not necessarily restored to the original state, different materials have completely different hysteresis characteristics.

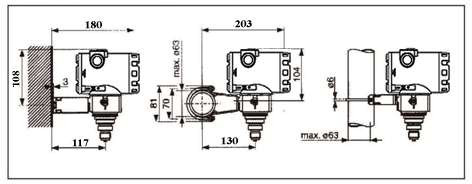

2.Mounting conditions

Surface conditions, installation torque, etc. is the biggest influence factors. Also refers to the installation conditions of the pressure sensor in the use of the site, such as surface conditions, contact area, installation torque, bolt strength, bearing surface hardness will affect. These influencing factors are sometimes mistaken for a deterioration in the hysteresis characteristics of the sensor.

These influences are in direct contact with the sensor, and there are other factors that seem to have little to do with the sensor itself, but affect the accuracy of the sensor. Examples of such factors are the strength of the scale platform, the robustness of the foundation, and the protection against dust and water. Dust and water are two factors that do not affect the sensor under good maintenance conditions, but require special attention when used outdoors. The reason is mainly due to corrosion of the sensor surface, so that the contact point changes, especially products containing accessories, rust will make the accessories and sensors "rust" together, and affect the accuracy. As for the effect of dust on the accuracy of the sensor, experienced users will adopt appropriate protective measures, such as increasing the sealing cover, the surface coated with an appropriate amount of grease and other protection.

Schematic diagram of pressure tube connection

After affecting the hysteresis characteristics of the sensor, thus affecting the measurement accuracy, should be avoided as much as possible in the process of manufacturing and actual use, in order to ensure the stability of long-term use of the performance.