Common Troubleshooting for 2-wire 4-20ma Pressure Transmitter

Common Troubleshooting for 2-wire 4-20ma Pressure Transmitter

The two-wire 4-20mA pressure transmittersare widely used in industrial applications like water tanks, oil pipelines, hydraulic and HVAC, etc. here are the most common faults and solutions for 2-wire 4-20ma Pressure Transmitter.

Working Principle

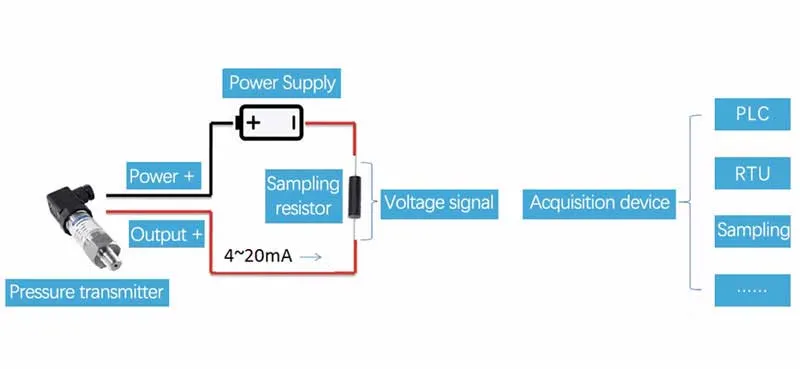

Figure 1

It is a typical usage of two-wire 4-20mA pressure transmitters for most customers showed in figure 1. After the pressure transmitter is powered on, the loop current is proportional to the pressure to generate a 4-20 mA signal by collecting the pressure. The current flow through the sampling resistor (typical 100 Ω, 250 Ω) which connects serially with the loop, and then it is converted to a voltage signal used for the back-end acquisition system. Generally, the sampling resistors will be integrated into the acquisition device.

Figure 2

Faults and Solutions

Common fault No. 1: The pressure signal is not collected and the value is obviously abnormal.

There are many reasons for this problem, such as the acquisition equipment problems, wiring errors or product quality issues. To solve the problem, please ensure that the transmitter works normally after power-on at first;

Solutions:

a. Check the wiring:

Check the wiring according to the label on the transmitter housing or manual. For our products, generally black wire is power-supplied and the red wire is output positive.

If you find that the wire is reversed, please don't worry about the damage issue. The conventional products have anti-reverse design and please re-wiring to fix the problem.

b. Measuring voltage:

After checking the wiring, adjust the multimeter to the voltage value to measure the voltage between the positive and negative output of the transmitter. The voltage value should be within the transmitter supply voltage range which can be found in the product label or instruction manual.

If the measured voltage value is incorrect, check if the equipment is normal.

c: Measuring loop current:

Disconnect the transmitter "output positive", adjust the multimeter to the current position series into the current loop to test the loop current value. Generally, the non-pressurized state is about 4mA (the gauge pressure transmitter range lower limit is 0).

When performing the above test, pay attention to the setting of the multimeter's current and voltage position. Refer to the settings of the above two multimeters.

After the three steps above, since the multimeter works normal for testing, if the loop current value is still not about 4 mA (0.5%FS accuracy, 3.92~4.08 mA), it can be judged as a product failure at first, please contact the after-sales department for further analysis.

Common fault No. 2: Transmitter test is inaccurate, out of tolerance, no change in pressurization, etc.

Solutions:

(1) It is recommended to statically place the product in the air to check whether the power supply voltage is normal. Put the product in the vertical direction, test circuit current whether the 4mA is accurate. For the products with 0.5%FS accuracy, the zero current should be between 3.92 and 4.08 mA.

(2) If the zero current of the product is normal, it is recommended to check whether the equipment is normal, whether the shut-off valve is open or not, whether the pressure pipe is blocked or not, etc.

(3) Check the pressure sensing diaphragm of the transmitter, if the diaphragm is damaged, the transmitter should only be returned to the factory for repair;

(4) If the above solutions cannot solve the problems, please contact the after-sales department for further analysis